Products & Services

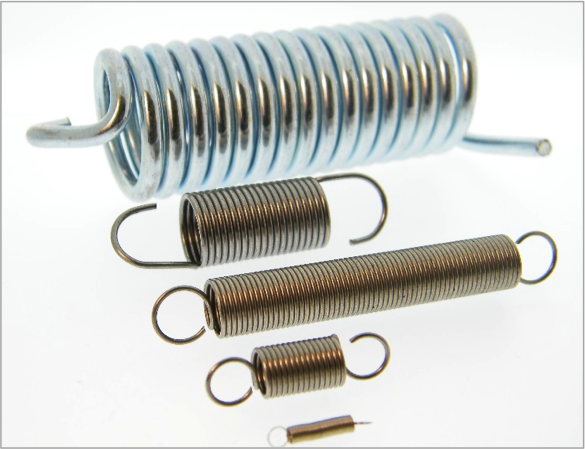

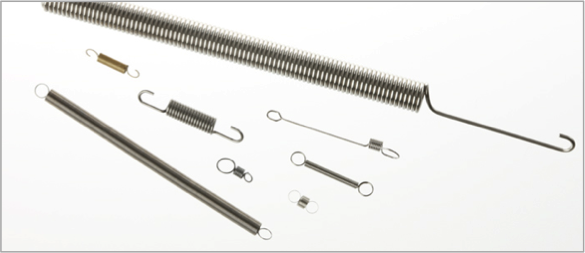

Extension & Tension Springs

Our Approach

Tension springs, unlike compression springs, are pulled rather than pushed in order to effect energy transfer. By virtue of this they have different end forms to anchor them and to allow actuation of the energy stored. The form of the ends is varied and virtually infinite in shape, to suit the user and the application.

However there are a number of commonly used shapes, the simpler of which provide a solution for the majority of applications.Tension springs are usually, but not exclusively, close coiled.

Advanex have experience and knowledge of wire forming materials as diverse as stainless steel, precoated material, spring steel, titanium, nitronic, phosphor bronze and pre hardened materials.

Our engineering and design team can support our customers with the design and development of the optimum product and production solution for their application.

Although, like compression springs, they have a nominally linear rate, when close coiled they are coiled with “initial tension”. This initial tension is introduced by the coiling process and is best described as “the amount of force that can be applied to the spring before the coils begin to open”.

There are limits to the amount of initial tension that can be coiled into the spring, which in general is a function of its material specification and the structural ratio of its diameters.

Advanex have extensive facilities around the globe for coiling tension springs from round and section materials and have developed a number of special end forms for the convenience and efficiency of our customers requirements.

With the ability to develop designs using hand-made techniques, we have a solution for you.